LK-Sealer-01 Multiwell Plate Sealers

Category: Quanti-Tray System

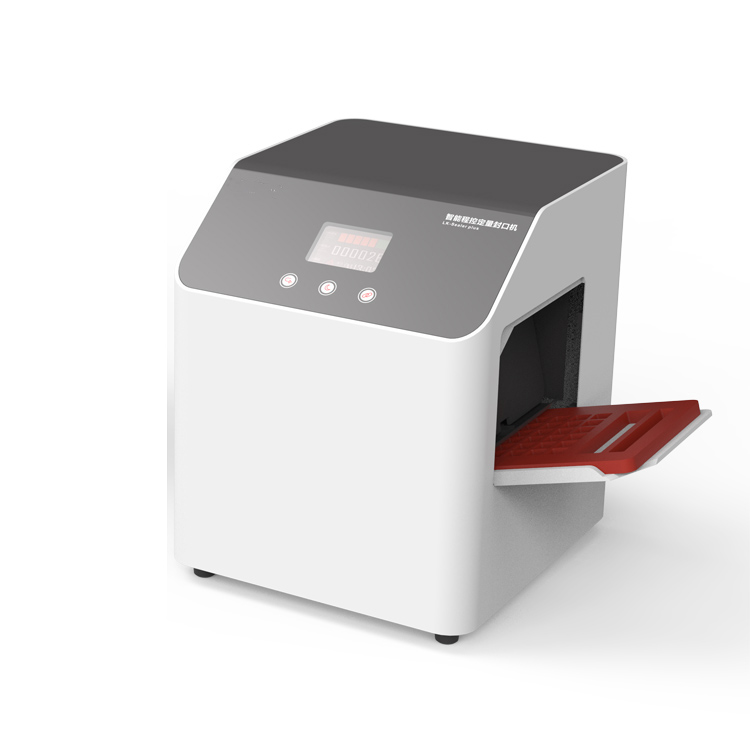

LK-Sealer-01 Multiwell Plate Sealers

The new product has undergone comprehensive improvements in terms of structure, materials,

and craftsmanship, redefining the industry benchmark. The instrument adopts a perfect arc design overall, which is beautiful and simple; The instrument status information is displayed using LCD, which is clear and intuitive; Using a whole curved organic glass as the instrument panel, it is fashionable and atmospheric; Intelligent touch panel buttons, user-friendly design, easy to operate; Adopting 3D silent cooling fan, accurate temperature control; With multiple fault code prompts, it provides users with ultimate safety assurance.

and craftsmanship, redefining the industry benchmark. The instrument adopts a perfect arc design overall, which is beautiful and simple; The instrument status information is displayed using LCD, which is clear and intuitive; Using a whole curved organic glass as the instrument panel, it is fashionable and atmospheric; Intelligent touch panel buttons, user-friendly design, easy to operate; Adopting 3D silent cooling fan, accurate temperature control; With multiple fault code prompts, it provides users with ultimate safety assurance.

PRODUCT SPECIFICATIONS

|

Model

|

LK-Sealer-01

|

|

Environmental temperature

|

-10℃~50℃

|

|

Relative humidity

|

20%~90%, without a large amount of dust and corrosive gas pollution

|

|

Shell temperature

|

<35℃

|

|

Preheating time

|

2~3min

|

|

Weight

|

14.25kg

|

|

Sealing speed

|

51 holes/97 holes fixed quantity detection disk Sealing time<9 seconds/piece

|

|

Detection range

|

matched with 51 hole fixed quantity detection disk Detection range:

0-200MPN/100ml (undiluted water sample); Combined with 97 hole fixed quantity detection plate, detection range: 0-2419MPN/100ml (undiluted water sample); |

|

Reliability:

|

No leakage or perforation after sealing

|

|

Convenience

|

The instrument can detect more than 50000 samples during its service life

|

|

Power supply voltage

|

220V ± 10%, 50Hz

|

Main advantages

1.Integrated aluminum alloy warehouse door

2.minutes of ultra fast preheating

3.high-end organic glass panels

4.HD LCD display

5.touch panel buttons

6.Convenient maintenance window

Preheating process

Display in both Chinese and English, with a preheating progress bar indicating the preheating status of the instrument, simple and intuitive.

Count statistics

Displayed in both Chinese and English, inheriting the sample quantity accumulation function completed by the previous generation sealing machine, while displaying it in concise numbers.

Fault code

A code that indicates an internal malfunction or abnormal situation of an instrument, which can help customers understand the status of the instrument.Simultaneously ensuring the safety of customer use.

Opening/closing reminder

The instrument is equipped with a highly sensitive probe that can detect the opening/closing status of the instrument, making it more automated and intelligent.

Clock display

For the convenience of laboratory personnel, the instrument is equipped with an electronic clock time display, allowing users to record their working hours.

Overall panel

The operation panel adopts an integrated molding of a whole piece of organic glass, with a perfect curved design and beautiful and fashionable appearance.

Waterproof button

The new generation of sealing machines have removed physical buttons and integrated cases on an organic glass panel, making them waterproof and safe. With a touch of your fingertips, you can complete reverse, sleep, and data connection functions, making operation safer and more convenient.

Sleep state

The new generation of sealing machines has added a sleep function, which can put the instrument into sleep mode when work is temporarily interrupted, avoiding safety hazards such as repeatedly turning on or off the machine or forgetting to turn it off.

Convenient maintenance

The new generation sealing machine has convenient maintenance functions, with dual internal and external door design. Pushing open the internal door can achieve cleaning and maintenance of the heating roller.

Direct discharge of leaked liquid

The new generation sealing machine is equipped with a direct discharge function for liquid leakage. Accidental liquid leakage during operation can be discharged from the machine through the bottom plate direct discharge port. The bottom plate after surface chemical treatment can ensure long-term use without rusting.

Be the first to review “LK-Sealer-01 Multiwell Plate Sealers” Cancel reply

Reviews

There are no reviews yet.