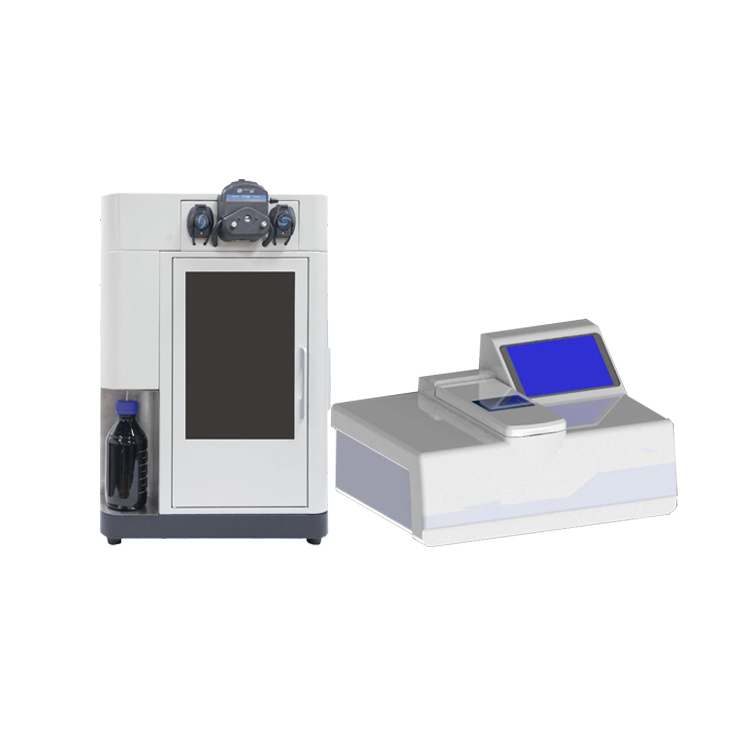

UP-A680P infrared oil measuring instrument

Category: oil measuring instrument

Tag: oil measuring instrument

UP-A680P infrared oil measuring instrument

The UP-A680P series fully automatic infrared oil measuring instrument is a professional instrument that achieves fully automatic measurement of oil, petroleum, and animal and vegetable oils in water. This instrument is fully developed in accordance with the national standard “HJ637-2018 Water Quality – Determination of Petroleum and Animal and Plant Oils – Infrared Spectrophotometer”. It has stable performance, high accuracy, and fast detection speed, and is an essential instrument in the fields of environmental protection, water conservancy, petroleum and petrochemical.

Working principle

The UP-A680P series fully automatic infrared oil analyzer uses the principle of similar phase solubility to extract oil from water into tetrachloroethylene. After oil water separation, the oil is measured, and the oil is measured after passing through a magnesium silicate adsorption column. Oil substances have absorption at spectral bands with wave numbers of 2930cm-1 (stretching vibration of C-H bonds in CH2 groups), 2960cm-1 (stretching vibration of C-H bonds in CH3 groups), and 3030cm-1 (stretching vibration of C-H bonds in aromatic hydrocarbons). Qualitative and quantitative analysis is conducted using absorption and conversion of spectral energy.

Application field

Suitable for laboratories, third-party testing institutions, research institutes, sewage treatment plants and other fields in industries such as petroleum and petrochemical, smelting, environmental protection, hydrology and water conservancy.

PRODUCT SPECIFICATIONS

|

Model

|

UP-A680P

|

|

Wavenumber scanning range

|

3400-2400cm-1

|

|

Wavenumber accuracy

|

±1cm-1

|

|

measuring range

|

0-80000mg/L

|

|

Absorbance range

|

0.0-1.999

|

|

accuracy

|

±2%

|

|

repeatability

|

<2%

|

|

detection limit

|

0.02mg/L

|

|

Graph resolution

|

±1cm-1

|

|

Measure Linearity

|

>0.999

|

|

Time

|

(5-10)min

|

|

Sample grade

|

8

|

|

Precision syringe range

|

0-100ml

|

|

Extraction ratio

|

(100~5):1

|

|

Oil water separation method

|

Separation of water barrier membranes

|

|

Automatic switching of magnesium silicate

|

hand movement

|

|

Sampling error

|

0.05ml

|

|

extraction efficiency

|

>98%

|

|

Automatic detection reagent

|

Yse

|

|

operating mode

|

Connecting a computer

|

|

Overall dimensions (mm)

|

Preprocessor: 540 * 450 * 720; Host: 540 * 310 * 210

|

|

Weight

|

Preprocessor:25kg, Host:24Kg

|

Technical advantages

1.Tetrachloroethylene testing: Automatically complete purity testing of tetrachloroethylene, and sample testing can only be carried out after passing the testing.

2.Independent cleaning position: Modular cleaning of the inner and outer walls, as well as the entire pipeline, effectively avoiding cross contamination. 3.Automatic switching of adsorption column: The magnesium silicate adsorption column can be automatically switched once for each sample detected, reducing cross contamination to a low level. 4.Accurate detection of aromatic hydrocarbons: Both benzene and toluene can be effectively detected, and the detection error is less than 3% for standard samples with different ratios. 5.The measurement methods for standard samples and water samples are consistent: when measuring standard samples or water samples, all samples are preprocessed and sent to the host for measurement, displaying the results. To further verify the impact of the preprocessor on the sample extraction results and minimize it.

Product features

accurate 1.Good stability: It adopts a cast aluminum base and undergoes natural stress aging treatment, resulting in good optical stability.

2.High accuracy: The instrument has a high degree of automation, reducing human error, and improving measurement accuracy and repeatability.

3.Accurate detection of aromatic hydrocarbons: Both benzene and toluene can be effectively detected, and the detection error is less than 3% for standard samples with different ratios. Make the instrument truly serve the actual water sample. 4.Moisturizing: Simulate manual testing to moisten pipelines and colorimetric dishes to improve detection accuracy.

5.Real time zero adjustment: Zero tracking technology, precise positioning, eliminating errors, making mechanical errors and temperature drift close to zero, with mechanical positioning errors less than 1 wavenumber.

intelligent 1.Fully automatic operation: Automatically complete processes such as tetrachloroethylene inspection, extractant addition, liquid-liquid extraction, oil-water separation, animal and vegetable oil separation, oil measurement, pipeline cleaning, and automatic reagent recovery.

2.Simultaneous measurement of three parameters: achieving simultaneous or separate measurement of total oil,

petroleum, and animal and vegetable oils. Using the three wave number correction coefficient method, there is no need to create a standard curve.

3.Maintenance management: Applying the concept of life management, the system automatically prompts maintenance information such as pipelines, components, and consumables, facilitating timely replacement by users and ensuring stable and reliable operation of equipment.

4.Sample grade: freely set 1-N sample grades, which can be measured non continuously.

5.Communication management: wireless and wired coexist, achieving seamless connection with computers, mobile terminals, and remote data platforms.

6.Special sampling bottle: Equipped with a dedicated sampling bottle for oil measuring instruments, the volume can be directly read, and the sample does not need to be transferred twice, and can be directly extracted on the machine.

security 1.Safety and health: The exhaust gas is adsorbed using activated carbon adsorption columns to prevent workers from coming into contact with tetrachloroethylene, and can not be used in fume hoods.

Remote control: can be operated off-site, creating a new mode of detection.

2.Extraction agent and water sample separation: The instrument can automatically store the extraction agent and water sample in different waste liquid bottles, reducing the amount of waste liquid treatment.

Efficient 1.High extraction efficiency: Bubble and jet extraction methods, with an extraction efficiency greater than 98%.

2.Suitable for various water quality: Suitable for high impurity water quality, without manual treatment and filtration, can be directly tested on the machine.

3.Fast analysis speed: The entire process only takes 5-10 minutes.

Be the first to review “UP-A680P infrared oil measuring instrument” Cancel reply

Reviews

There are no reviews yet.